UNIFIED ROBOTICS II: Sensing

- smeltingpottutoria

- Dec 11, 2016

- 2 min read

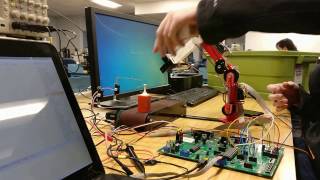

For this WPI Robotics Engineering course, students were required to build a robot for the purpose of autonomously locating and extinguishing a candle in a maze field configuration. Constraints were placed on robot size and required use of certain sensors. An IMU in addition to encoders on a differential drive base was used to accurately track position in real-time.

The traditional approach that many students have followed is the use of ultrasonic sensors to wall follow one side of the maze until the robot senses a flame. My group decided to go beyond the scope of this challenge and add addition sensors to efficiently and rapidly locate and extinguish the candle.

The approach adopted by our team was to use a 360 degree planar LiDAR to map out the maze and use path planning algorithms to find the fastest path. An XV11 Neato lidar was used because of its low cost. In addition to using a LiDAR, a different processor than the one provided was used. A goal was set to stick with an embedded 32bit architecture instead of opting for a more powerful but power hungry system (raspberry pi, beaglebone). A teensy 3.6 was selected because of its impressive specs for its cost.

Here is a top down view of the chassis of the robot. The frame was designed to be modular so different top pieces could potentially be swapped on instantly. A 32 pin custom made .1" pitch header was made to accomplish this. The custom 18650 lithium ion battery pack can be seen in the bottom covered by a 3d case to protect it from potential hazards.

Here is a short clip of the top lcd cover being printed on a form 2 SLA print.

A demonstration of flame tracking with the blob IR camera and tilt of fan.

A full written report can be found at http://bit.ly/2jSrLcL

Comentários